Custom & Engineering Capability

Balmer is uniquely equipped to work with architects, designers and contractors to execute custom designs of moulded architectural art. Our designers and craftsmen are unsurpassed in their knowledge and skill working with clay, plaster, steel, and wood to build original models which we mould and cast in a variety of materials.

Renovations, restorations, and individually designed custom works for homes, condominiums, apartments, hotels, theaters, restaurants, offices, board rooms, stores, churches, government buildings, courthouses and embassies are all specialities in which Balmer excels.

Manufacturing & Design Facilities

Balmer can supply any size project, large or small, directly from our 120,000 square foot manufacturing and design facilities. In stock, made to order, and custom manufactured products are consistently delivered on time and within budget.

Custom products are engineered to meet the specific requirements of the client and simplify installation. Shop and installation drawings are created on CAD workstations for client review prior to manufacture.

Complete, Engineered Custom Fabrications

One reason for approaching Balmer for a factory cast custom product is the expense and time required to install delicate, individual elements of enrichment on site. In the past, most, if not all, ornamental plaster was built in place by skilled craftsmen. Throughout our history, Balmer has completed many such projects.

Today, with tight construction schedules and high construction labor rates, there is a better way to build. It is possible, for example, to have Balmer fabricate a complete, one piece, custom designed panel which might incorporate multiple coffers, beams, and beam intersections. The cast panels can be delivered, ready to install as soon as drywall work is completed.

Instead of building up a complex cornice on site from component parts, Balmer can design and cast a complete custom cornice in one piece lengths which install quickly, easily, and precisely.

These are just two examples. With this approach, not only are labor costs reduced, but the construction schedule can benefit immensely. Custom manufactured parts can be available as soon as the project requires them: engineered for quick, secure, and precise installation.

Enrichments

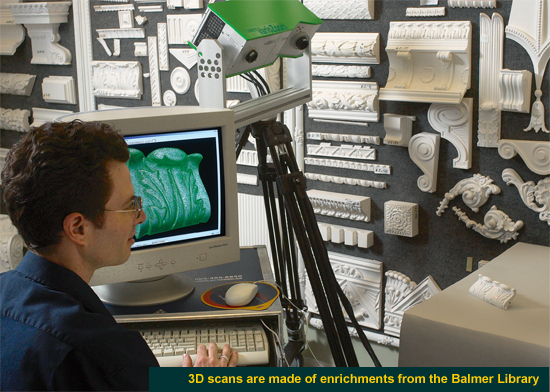

Balmer's library of patterns is one of the most extensive in the world - over 12,000 patterns in all. The Balmer library includes all classical enrichments in various sizes, shapes, and styles: egg & dart, dentil, pearl, acanthus leaf, water leaf, greek key, leaf & dart, and so on. Enrichments from the library are often used in the creation of the models for custom designs. They are frequently scanned, then altered, modified and adjusted using computer aided design techniques to meet the exact requirements of a custom application. Several scalable enrichments are presented in this guide. Advice for their specification in your design is provided on page 131.

3D Scanning & Printing Meet The Old World

Balmer provides custom hand sculpting, 3D scanning,

3D computer aided design, and rapid prototyping

using 3D printing technology. These capabilities allow us to precisely meet your custom requirements on time and on budget. This combination of old and new modeling techniques is unique to Balmer.

Restoration

According to the Oxford Dictionary, restoration is an attempt to bring (something) back to (its) original state; renovation is restoring to good condition. Throughout our history, Balmer has been extensively involved in both restoration and renovation. Relatively few people today need, want, or can afford to have things exactly as they were. For most,

The approach taken in the historical restoration of ornamental plaster depends on the degree of damage or decay of the existing ornament. In situations where there is minimal damage, and no structural danger, repairs are conducted on site by skilled plaster craftsmen. Balmer staff can be provided for such work.

When there is major damage, Balmer's CAD designers and mould shop become involved. Here, working from sample ornaments retrieved from the site by a contractor, Balmer performs 3D scans, creates 2D and 3D CAD designs, and then models replacement components. Replacement ornamentation is then cast (complete with integral steel structural supports where appropriate.) The result is an engineered part which installs easily on site and is far more secure and durable than the original ornament.

Experience

Balmer has participated in many prestigious projects, including:- Loew’s Hotel, Miami

- Portofino Hotel, Orlando

- The Bellagio Casino, Las Vegas

- The Venetian Casino, Las Vegas

- The New Amsterdam Theatre, New York

- The St. Regis Sheraton Hotel, New York

- Essex House, New York

- The Plaza Hotel, New York

- The Metropolitan Museum of Art, New York

- The Pantages Theatre, Toronto

- The Royal York Hotel, Toronto

as well as numerous private homes, condominiums, apartments, retail stores, and restaurants throughout North America.